- Tel: 0086 -21-31006099

- WhatsApp: 8618621659750

- E-mail: market@ruccachina.com

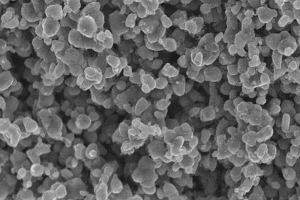

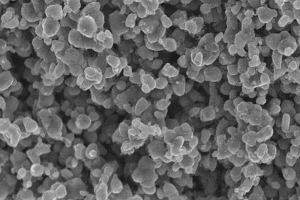

N -nano horizontal bead mills adopt qualified sintered ceramic material by high temperature as contact materials of the mills. Both laboratory and industrial equipment are available. High wearing resistance, high working efficiency, zero metal pollution, nano- grade ultra-fine grinding.

Features

1. Patented inverted- triangle pin structure create bigger action area for the grinding media. Bigger shearing force , high wearing resistance and higher efficiency.

2. Efficient double jacket cooling systems for grinding chamber and discharging end cap. Special independent pressurized cooling tank for mechanical seal. The dissolvent which is compatible with grinding material can be added as cooling agency to reduce the production loss in case of any leakage problem.

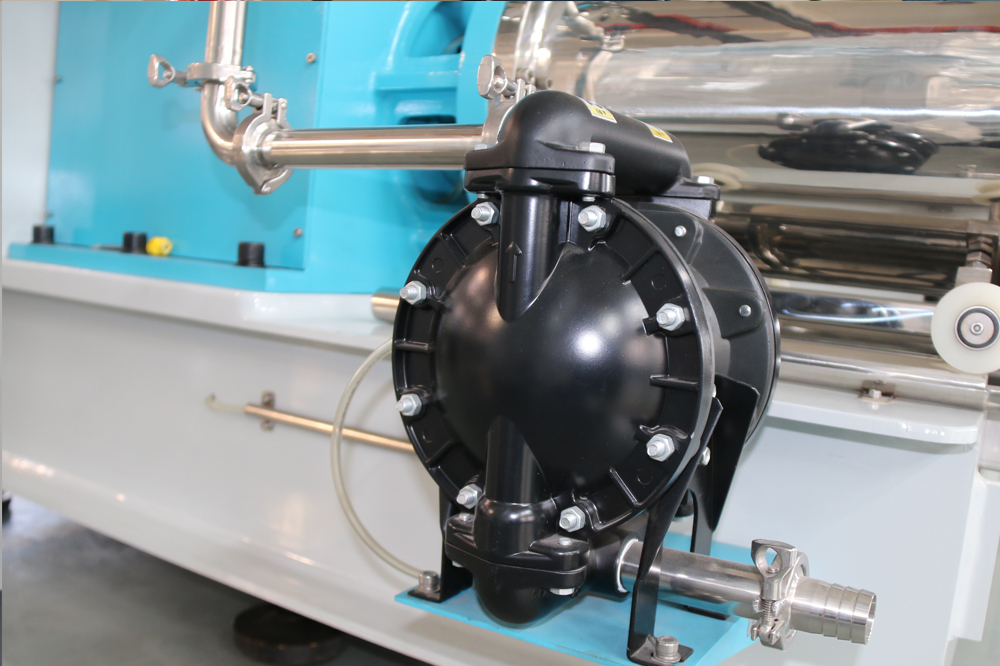

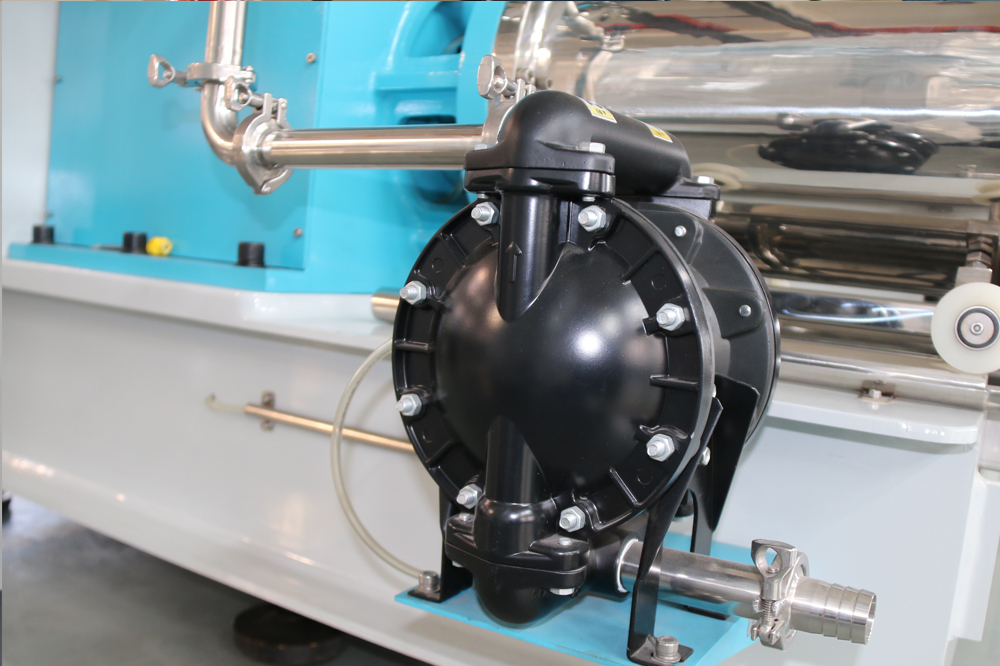

3. Feeding device: pneumatic diaphragm pump, frequency control gear pump, screw pump and peristaltic pump optional as clients' requirements, contact material with good solvent resistant property.

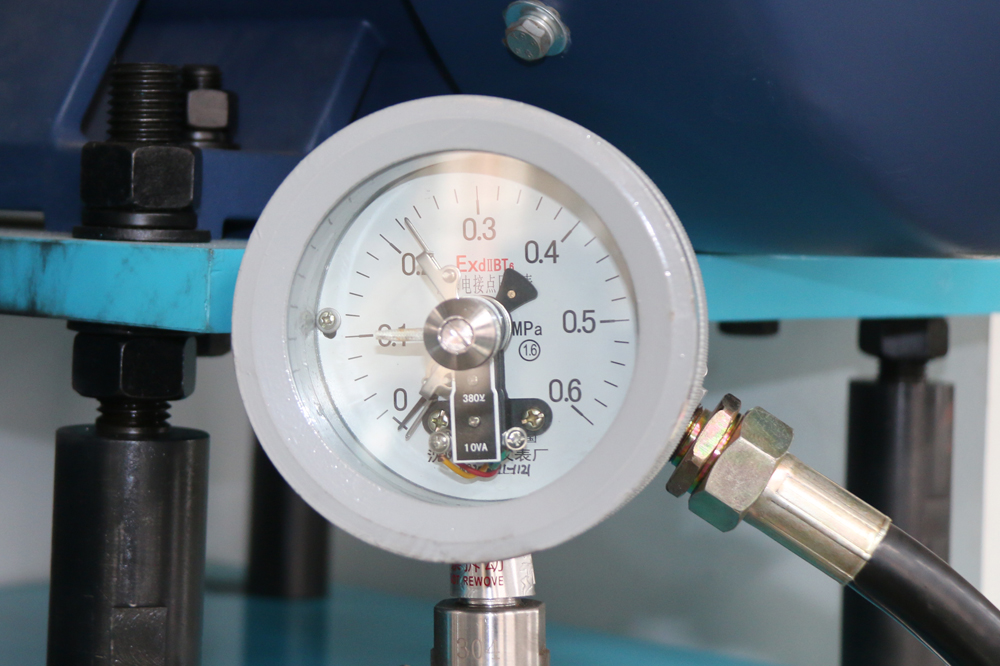

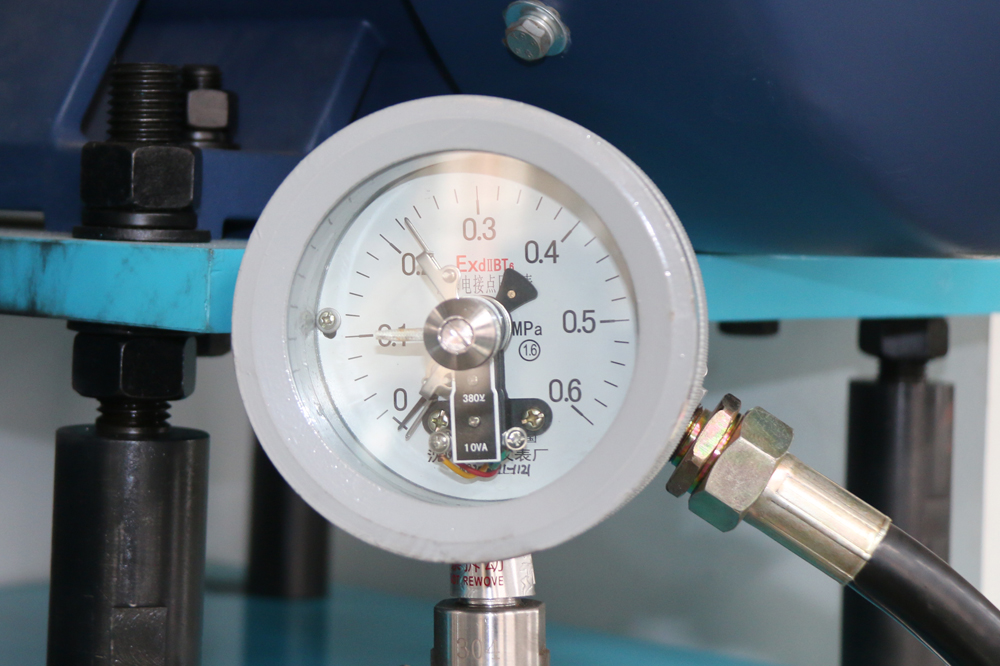

4. High security property, with auto-stop function when pressure and temperature value is up to the set limit or coolant level of mechanical seal is lower than required.

5. Reasonable design for inner and outer structure allows stable performance with no vibration and noise.

6. Frequency control and PLC are optional

7. With CE&ISO9001:2008 qualification.

Application

-

inkjet ink

-

digital ink

-

ceramic ink

-

lithium battery

-

pharmaceutical material

-

fluorescent brightener nano coating

-

nano material

-

polishing agents for electronic components

Technical data

|

Parameter |

Total volume |

working volume |

Power |

Batch |

Cooling coolingWater |

Max line |

|

N1 |

1.8 |

1 |

3 |

2~10 |

100 |

12 |

|

N2 |

3.6 |

2 |

5.5 |

3~20 |

100 |

12 |

|

N6 |

11 |

6 |

15 |

200~1000 |

1000 |

14 |

|

N10 |

17 |

10 |

18.5 |

300~1000 |

1500 |

14 |

|

N20 |

35 |

20 |

30 |

500~1500 |

2000 |

14 |

|

N30 |

45 |

30 |

45 |

500~2000 |

2000 |

14 |

|

N60 |

110 |

60 |

75 |

1000~3000 |

2500 |

15 |

|

N150 |

290 |

150 |

160 |

2000~5000 |

4000 |

16 |

|

N400 |

780 |

400 |

320 |

3000~8000 |

6000 |

16 |

-

PLC

-

Motor

-

IngersoII Rand diaphragm pump

-

instrument panel

-

N series bead mills are suitable for nano grade ultra-fine grinding of materials sensitive to temperature and metal pollution.

- They can be applied in industrials such as inkjet ink, digital ink, ceramic ink, lithium battery, pharmaceutical material, fluorescent brightener nano coating, electric slurry, heat-sensitive paper coating etc.

2. Efficient double jacket cooling systems for grinding chamber and discharging end cap. Special independent pressurized cooling tank for mechanical seal. The dissolvent which is compatible with grinding material can be added as cooling agency to reduce the production loss in case of any leakage problem.

3. Feeding device: pneumatic diaphragm pump, frequency control gear pump, screw pump and peristaltic pump optional as clients' requirements, contact material with good solvent resistant property.

4. High security property, with auto-stop function when pressure and temperature value is up to the set limit or coolant level of mechanical seal is lower than required.

5. Reasonable design for inner and outer structure allows stable performance with no vibration and noise.

6. Frequency control and PLC are optional

7. With CE&ISO9001:2008 qualification.

|

Parameter |

Total volume |

working volume |

Power |

Batch |

Cooling coolingWater |

Max line |

|

N1 |

1.8 |

1 |

3 |

2~10 |

100 |

12 |

|

N2 |

3.6 |

2 |

5.5 |

3~20 |

100 |

12 |

|

N6 |

11 |

6 |

15 |

200~1000 |

1000 |

14 |

|

N10 |

17 |

10 |

18.5 |

300~1000 |

1500 |

14 |

|

N20 |

35 |

20 |

30 |

500~1500 |

2000 |

14 |

|

N30 |

45 |

30 |

45 |

500~2000 |

2000 |

14 |

|

N60 |

110 |

60 |

75 |

1000~3000 |

2500 |

15 |

|

N150 |

290 |

150 |

160 |

2000~5000 |

4000 |

16 |

|

N400 |

780 |

400 |

320 |

3000~8000 |

6000 |

16 |